F-7 Resin Casting

F-7 Resin Casting10.05.2005

This is my first attempt of making a resin cast off an MTL F-7 locomotive shell.

The first attempt went pretty okay with a few things learned after this.

F-7 Resin Casting F-7 Resin Casting10.05.2005 This is my first attempt of making a resin cast off an MTL F-7 locomotive shell. The first attempt went pretty okay with a few things learned after this. |

Here is the material I used for the making off the mold and the actual cast.

Wacker Silicones: Elastosil 4601 A/B for the rubber mold making. (1+1=2Kg)

Renshape: Rencast FC 55 A/B for the actual cast resin making. (1Kg)

Price: About 800, - ($125)

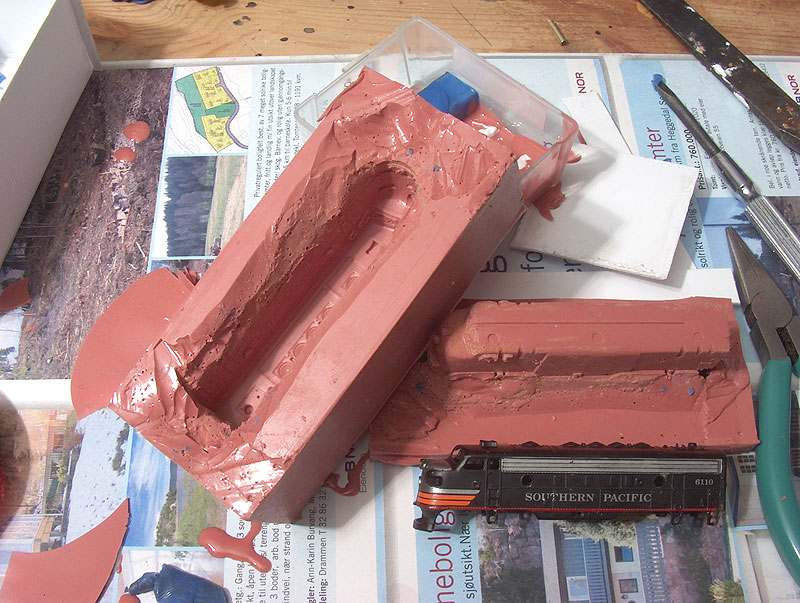

First I filled the

shell with modeling plaster.

Then I build a

container with some styrene and pleased the shell at the bottom.

Then I mixed the

rubber mold (9:1). You have pretty god time to work with the mix before it

begins harden. Up to 90minutes in Room temperature. Before I purred the mix over

the shell I banged the mixing bowl on a hard surface to let out al the air

bobbles. It's a lot off them and as you can see it still is a lot off airbobbles

after I purred it on. Let it set a little and bang the shell some more to get

out most of the airbobbles. Later on I think I will try to make some kind off

vacuum contraption to get all the airbobbles out. If you let it dry in room

temperature most likely the airbobbles will not bee a problem.

I tested the curing time with the left over from the mix in the stove at about

50-70C. It then took about 20-30minutes and the rubber was finished and ready

for use. According to the datasheet it should take 20minutes at 70C.

I left mine in for about an hour to be shore.

After removing the

modeling plaster I glued on some tubes to the shell on all the highest parts to

let the air out when filling the resin. PS: The tubes where filled with modeling

plastic so the the next mix off molding would not fill the holes.

You do not need to use tubes, solid rods would be better I guess for next time.

One thing I forgot before pouring the next mix was to put on a coat off

pharmacy Vaseline or on the surface off the first

mold. When I tried to take it apart the two rubber mold was pretty good glued

together. I had to cut open parts off the mold to get it apart. And therefore

the mold got damaged and the steering holes were lost. Fortuneless I managed to

save it pretty good and it had enough steering to make my first cast.

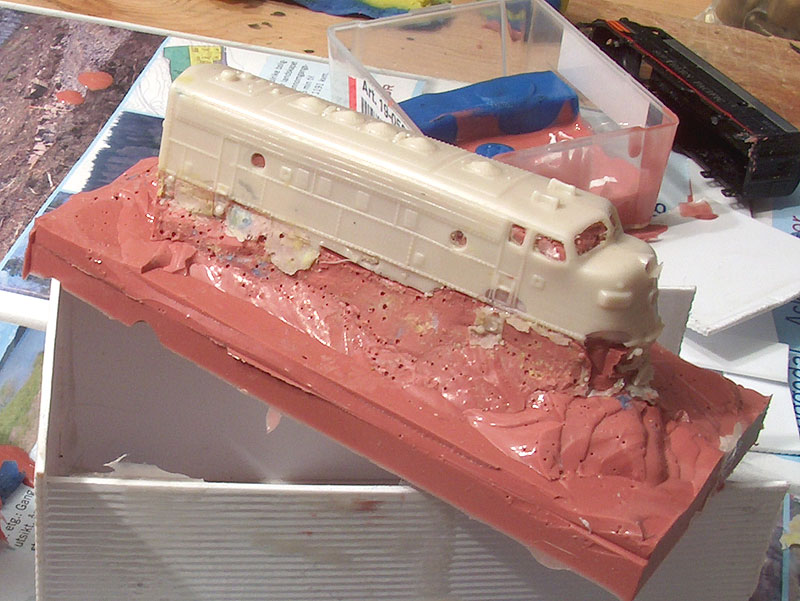

The Resin casting material is mixed 50:50 and you do

NOT have a lot off time to pure the

mixture in to the mold. ONLY ABOUT 1minute or little more before it begins to

harden. So you better be ready to pure right away. I was a little slow and I did

not think the resin would go down in all the crevices before it hardens. After

about 30minutes or so I Opened the mold and saw that It actually worked cuite

well after all. It was still a little soft when I took it out but it held its

shape good. Next time I will let stay in the mold for at least a couple off

hours before taking it out off the mold. Since I messed up the second half off

the mold the casting was not so good at the front skirt, ladders and around the

skirts.

But all in all I'm cutie pleased with this wary first attempt off making a

casting off my MTL F-7 shell.

Now I can try out some different paint combinations without destroying the

orginal.